Moving Dirt With Accuracy and Efficiency With Geospatial Technology

Think about the job of a site developer, like Gaines and Company. They design, plan, move, level, and grade dirt to predetermined specifications. We’re not talking about just a couple of acres. We’re talking about projects that are 50, 60, 70 – even 100-acre plots of land. Trees are cleared or preserved, water features are protected, obstacles are avoided. And all this work is completed with a tolerance of just two-tenths of a foot – that’s less than three inches! How do they do it?

Gaines’s geospatial experts answered that question. And, as you can imagine, it wasn’t a simple answer.

Meet Gaines’s technical managers in its Maryland and North Carolina offices – John “JD” Reid (Maryland) and Patrick Novak (North Carolina).

JD’s expert CAD and GPS involvement has spanned Gaines and Company’s projects for nearly a decade. Because of Gaines’s continual growth, Patrick joined the team in 2023. He has been a natural fit and brings a unique perspective to the organization.

When Gaines first gets a job, JD and Patrick estimate the amount of earthwork based on initial drawings from an outside engineering firm. This is done by resurveying a plot of land after a surveyor locks in survey points.

“I take our information from that initial survey and put it into my software to make a cut/fill map. This helps me figure out where we are heavy (too much dirt) or light (too little dirt). That tells us how much dirt we need to import or export,” said JD.

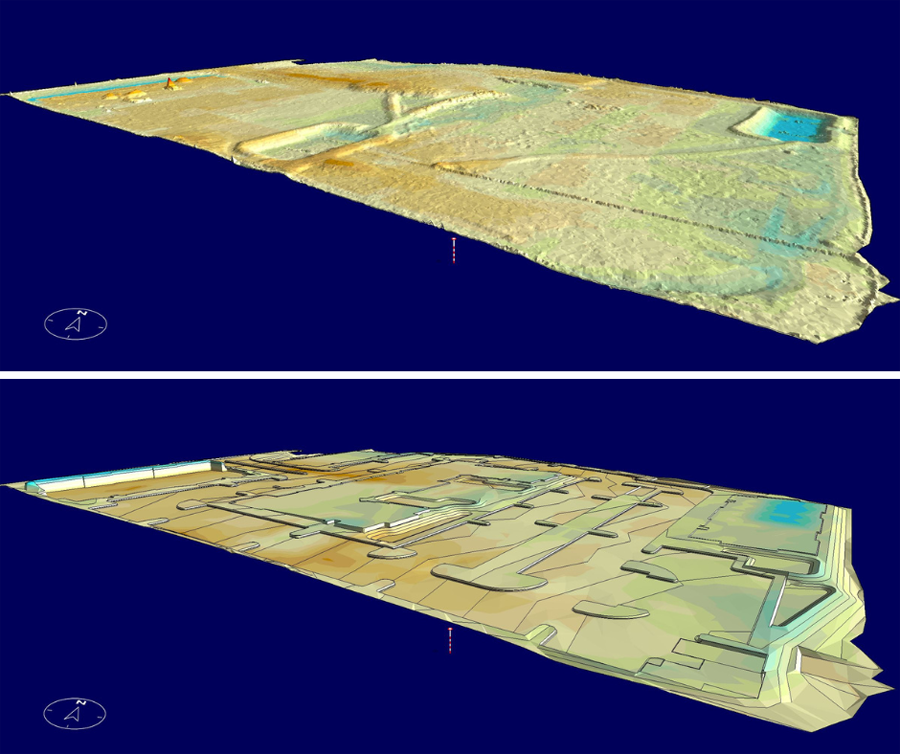

Gaines used drone technology to create site topography (top) and 3-D site design (bottom) renderings for a development project in Brandywine, Maryland.

JD and Patrick then set 6×6 posts in the ground for a base and rover system.

“The bases on top of the posts transmit signals to GPS units within our dozers and excavators. This tells our operators where and to what elevation to dig and move dirt,” added JD.

GPS units within the dozers and excavators display color-coded measurements that let the operator know how close they are to the model’s measurements. GPS measurements display green if on track and red if measurements do not match the model. JD and Patrick closely monitor the units to ensure they are reading accurately throughout the duration of the project.

GPS unit within a dozer. The green rectangles at the bottom of the GPS screen indicate that the grade is measuring to programed design measurements.

While the project is underway, JD and Patrick utilize photogrammetry – or hundreds of photos taken from drones and transmitted via satellite – to generate more accurate conditions of the job.

“Photogrammetry can get me within a couple inches of accuracy,” said JD. “So I take that information and make my own as-built topography drawing and compare it to the proposed drawings from Engineering.”

Photogrammetry (drone imagery) of an active project site.

“Photogrammetry can get me within a couple inches of accuracy,” said JD. “So I take that information and make my own as-built topography drawing and compare it to the proposed drawings from Engineering.”

Of course, changes are sure to arise from unexpected issues or design alterations.

“As a project manager, we are always looking steps ahead while remaining agile for the inevitable challenges and revisions,” said Project Manager Keith Eagle. “We talk with our CAD/GPS team daily to keep everyone informed.”

It’s not just Gaines’s project managers that JD and Patrick work with on a daily basis. They are also in continuous communication with Gaines’s supervisors, foremen, and the developer to stay informed about project changes.

“I’ve had projects with up to 16 different changes from the model. Clear communication and keeping up with changes can be a challenge, but it is essential for project efficiency,” said JD.

Excavator and dump truck exporting dirt from one area of the project site that measured heavy – or had too much dirt compared to the model.

At the conclusion of the project, JD and Patrick work with the owner to ensure the project was completed within the two-tenths of a foot tolerance.

“It’s always fun to see a project come together – seeing how far we’ve come from the original model to seeing it come to life on site,” said Patrick.

JD added, “I’m proud to play a part in the foundational stages of these massive development projects. It’s a cool thing to be part of.”

Gaines and Company is a full-service grading and excavation company with offices in Maryland and North Carolina. The organization has 70 years of experience in underground utilities, grading and excavating, sediment and erosion controls, and road work. Gaines and Company delivers safe, reliable, turnkey site development services in Maryland, North Carolina, Washington D.C., and Delaware on time and within budget.